Products

Fabricated Products

As a piping solution provider, Canadoil Group provides customers the value added concept, the One-Stop Shop, started from engineering design to components manufacturing and fabrication in one stop.

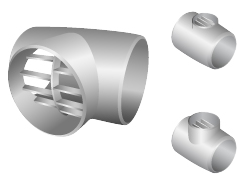

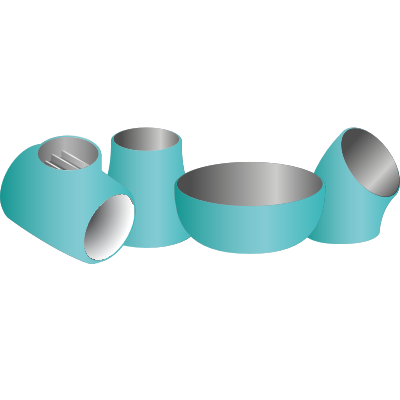

A Barred Tee is a special type of Tee fitting that features welded steel bars inside the branch outlet to prevent the fouling of pipeline tools travelling inside the main pipeline.

Diameter: 406.4 mm (16’’) – 1219 mm (72’’)

Thickness: 9.53 mm (3/8’’) – 50 mm (2’’)

Materials: Carbon, High-Yield Carbon, Stainless steel, Alloy, Clad

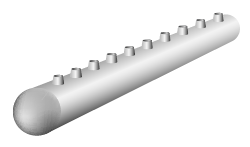

Header is a pipe with numerous extruded outlets and usually serves to collect or distribute fluid from a series of smaller pipes.

Size: 20’’– 48’’

Thickness: 12.7 mm (0.5’’) – 50mm (2’’)

Max length: 36.5 meters (120 ft)

Max weight: 40 metric tons (88,000 lbs)

Materials: Carbon, High-Yield Carbon, Stainless steel, Alloy, Clad

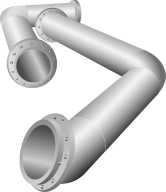

- Spooling is a prefabrication component. It is used as a part of various engineering products

- Size : 2” – 120”

- Thickness : 6mm (0.25”) – 50mm (2”)

- Seamless : 2” – 16”

- Two Seams : 16” – 120”

- Materials : Carbon, Stainless Steel, Alloy, Duplex, Super Duplex, Clad

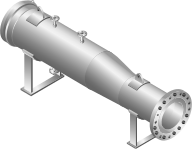

- Slug catcher is a versatile device for separating liquid and solid particles from pipeline gas. It is also a device for catching and storing slugs which are generated from frictional loss and heat loss of gases during traveling through long distance pipeline

- Pig launchers are used to launch the pig, which is a piece of equipment used to internally clean, scrape and survey a pipeline, into the pipeline, and pig receivers are used to receive the pigs after they have made a successful run

Diameter: 304 mm (12’’) – 1524 mm (60’’)

Thickness: 9.53 mm (0.375’’) – 100 mm (4’’)

Type of coating:

- FBE (Fusion Bonded Epoxy), a plant powder coating developed for Oil and Gas application.

- PE (Polyethylene), a multilayer coating consisting of a layer of fusion bonded epoxy, a copolymer adhesive and an outer layer of polyethylene which offers tough and durable coating.

- PP (Polypropylene), a multilayer coating consisting of a layer of fusion bonded epoxy, a copolymer adhesive and an outer layer of polypropylene.

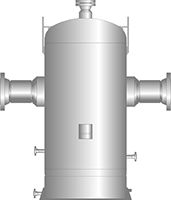

- A pressure vessel is a closed container designed to hold gases or liquids at a pressure different from the ambient pressure.

- Size : 24” – 320”

- Thickness : 6mm (0.25”) – 150mm (6”)

- Two Seams : 24” – 320”

- Materials : Carbon, Stainless Steel, Alloy, Duplex, Super Duplex, Clad

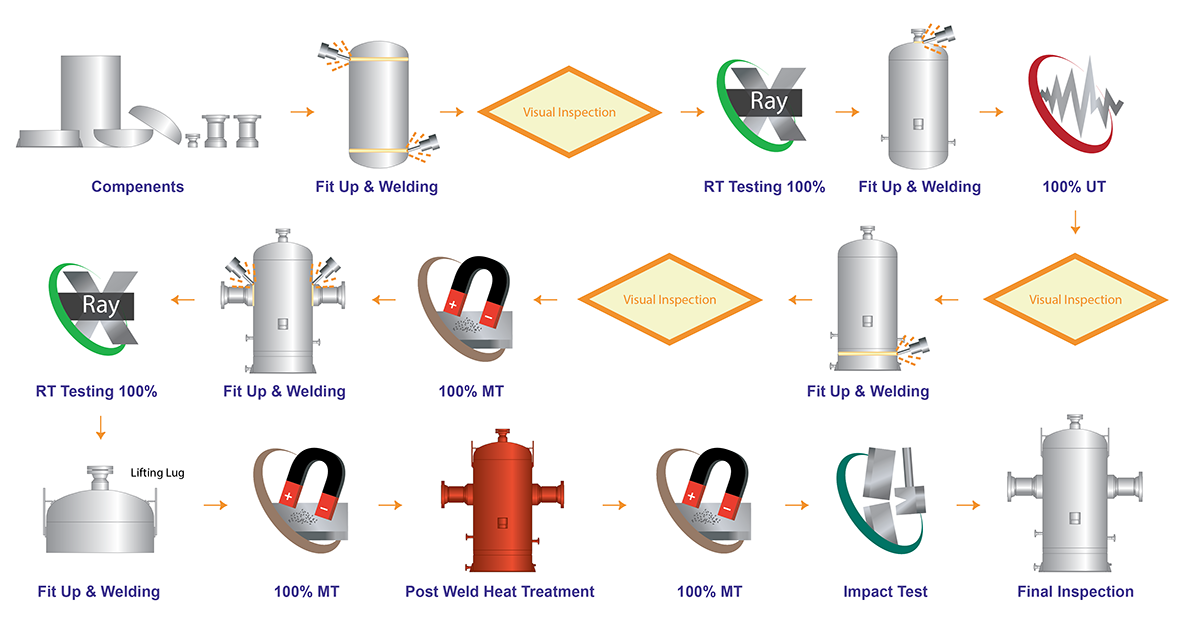

Manufacturing Process

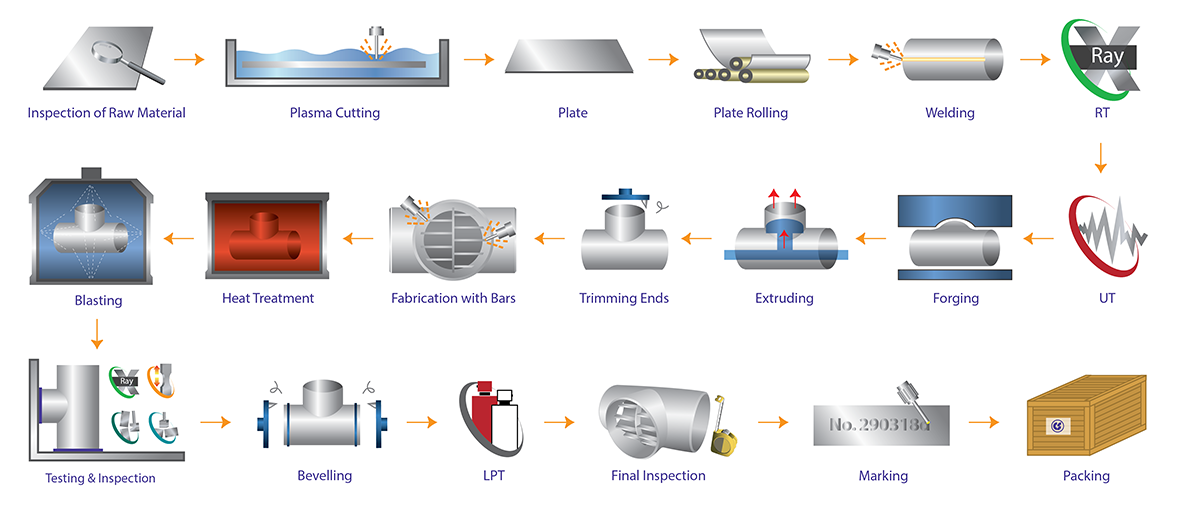

- Barred Tee

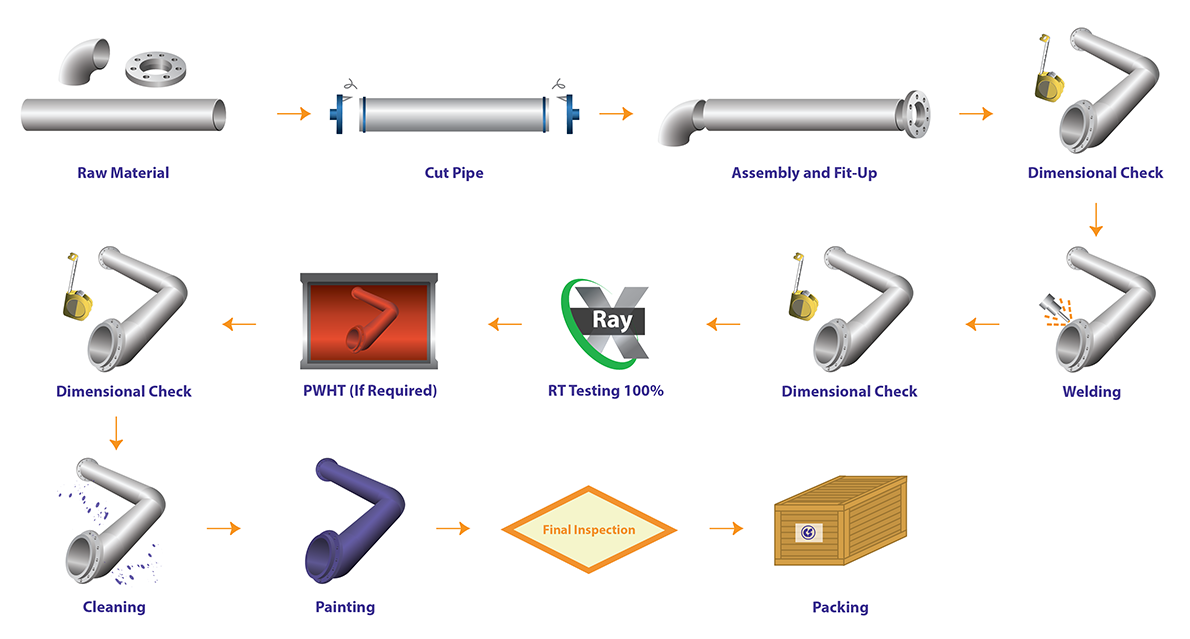

- Spooling

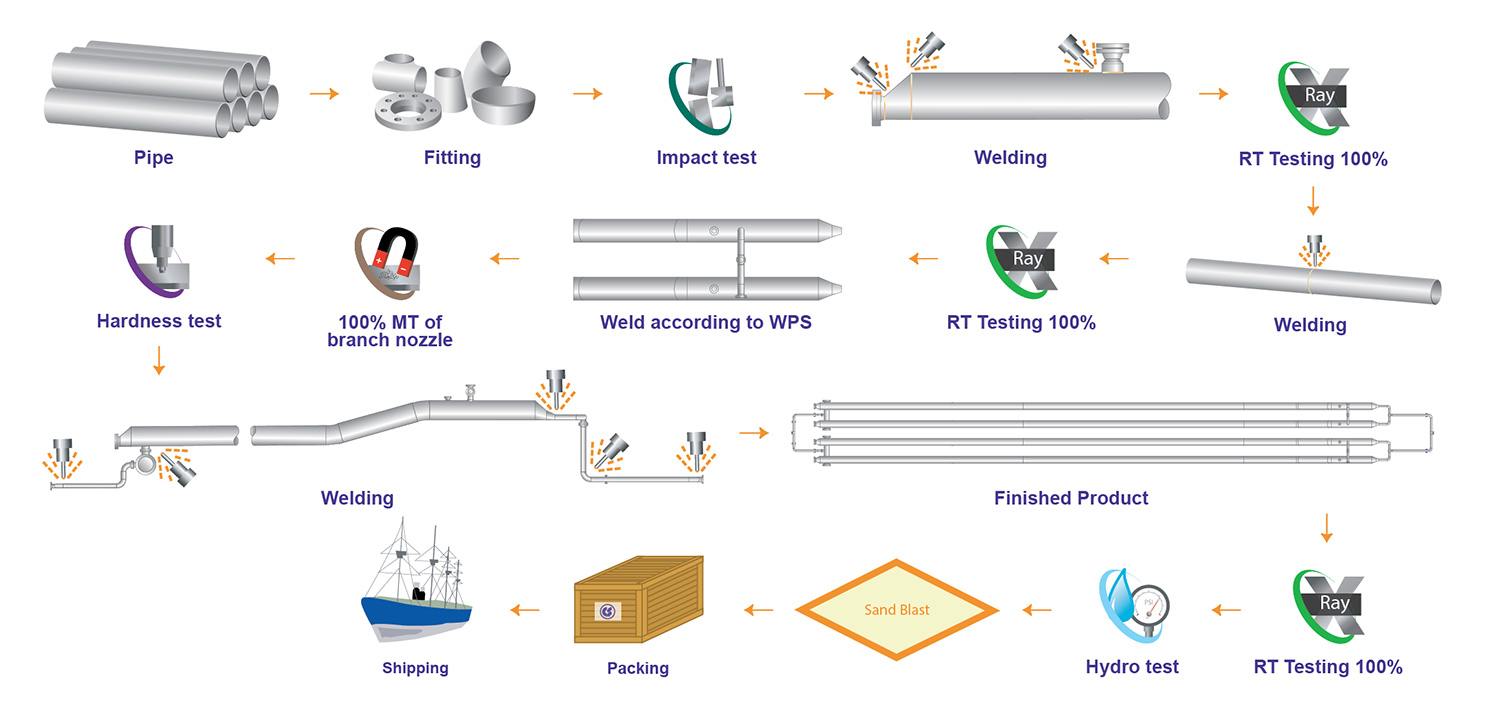

- Slug Catcher

- Pig Launcher and Receiver

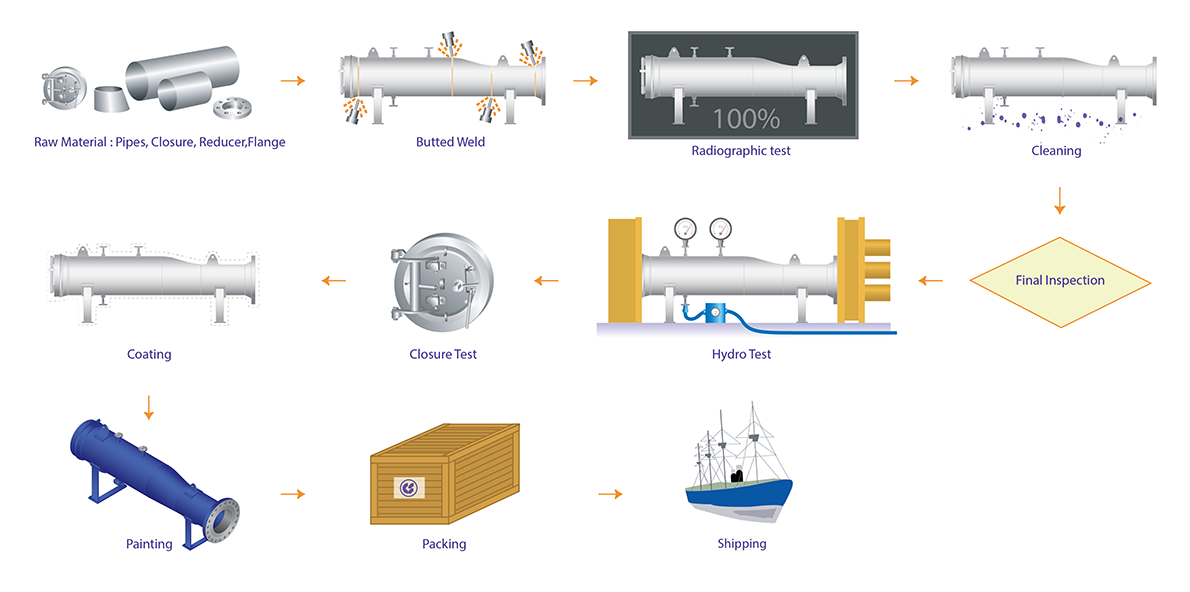

- Pressure Vessel